When it comes time to replace the anode rod in your water heater, you may be wondering if you should buy an aluminum or magnesium rod. Wrong selection could lead to accelerated corrosion of the water heater tank.

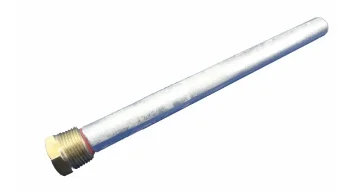

The anode rod attracts sediment and corrosive elements, which cause them to attack the rod instead of your water heater tank. The two most common types of anode rods are aluminum and magnesium.

However, there are several things you should know about water heater anode rod aluminum vs magnesium. Let's compare them!

How does Water Heater Anode Rod Aluminum vs Magnesium Differ?

When it's time to choose a water heater anode rod, you need to focus on the rod's all information. Even a small difference in the alloy composition can lead to a huge difference in the resulting corrosion rate.

The following are some of the main differences between aluminum anode rods and magnesium anode rods:

Material

Aluminum rods are made of aluminium alloys, while magnesium anode rods are made of manganese alloys.

On the other hand, magnesium anodes are about twice as heavy as aluminium rods used in tank-based water heaters.

Electrical Conductivity

Magnesium anode rods are more electrically conductive than aluminum anode rods. Their higher electrical conductivity means they will accumulate more electricity over time than aluminum anodes.

Corrosion Rate

Just aluminum rods have a much slower corrosion rate than magnesium anode rods.

This is because aluminium alloys are more resistant to corrosion than manganese alloys.

Frequency of Replacement

Aluminum anode rod replacement is usually less frequent than magnesium anode rod replacement.

This is because the aluminium alloy in the anode rod protects your system from corrosion for a longer time than other alloys do.

Manganese has a much lower melting point than aluminium. This means that when heated, it will enter into gas form before aluminium does.

Effectiveness

Manganese anode rods are more effective at corroding than aluminium rods. This is because manganese is a more active metal than aluminium.

In addition, magnesium rods have a better surface area to volume ratio than aluminium alloy ones.

Sediment Buildup

Sediment buildup is more common with metallic rods than aluminum anodes.

This is because magnesium corrodes faster than aluminium, which leads to more sediment buildup.

Health Concerns

There are some health concerns associated with the use of aluminium anode rods.

Some people are concerned that the aluminium in the rods may leach into the water and cause health problems.

Manganese ones do not have this same health concern.

Water Smell

Some people have reported that water heated with an aluminum anode rod has a metallic taste and smell. This is because of the aluminium oxide that is formed when the rod corrodes.

A manganese rod creates a rotten egg smell when they corrode. Fortunately, this smell is not harmful to humans or pets.

Water pH

An aluminum rod can slightly raise the pH of your water. This is because aluminium oxide is a basic compound.

Manganese ones do not have this same effect on water pH.

Ease of Installation

An aluminum rod is difficult to install because of its low melting point. On the other hand, water heater anode rods made of manganese are very easy to install and replace during a water heater repair.

Cost

Since aluminium is a cheaper material than manganese, you'll find that aluminium ones are also significantly less expensive.

As you can see, there are some major differences between water heater anode rod aluminium and manganese.

Although both types of rods can protect your tank from corrosion, it is important to understand the benefits and drawbacks of each before you buy one for your home.

Types of Anode Rods for Water Heaters

In the water heater anode rod aluminum vs magnesium sector there are typically three types of anodes that are used in water heaters: aluminium, magnesium, and zinc anode rod.

Aluminum anode rods are the most common type. They are less expensive and complecated to install than manganese or compare zinc anode rods, but they are not as effective at corroding.

Anodes made of manganese are more effective at corroding than aluminum anode rods, but they are more expensive and easy to install.

Zinc anode rods are the most effective at corroding, but they are also difficult to install.

It is important to choose the right anode rod for your water heater based on your needs and budget. Talk to a plumbing professional to learn more about your options.

When Should You Replace Your Anode Rod in Your Water Heater?

There are several signs that you should look for to know when it's time to replace the anode rod in your water heater:

- You may notice a decrease in water pressure if the anode rod is corroding.

- The anode rod may be corroding if you notice a metallic taste or smell in your water.

- There may be sediment buildup at the bottom of your tank because your anode rod is corroding.

- When the pH of your water changes, it may be caused by corrosion of the anode rod.

- If the anode rod is visibly corroded, it's time to replace it.

When you notice any of these signs, it's time to replace the anode rod in your water heater. This will help protect your tank from corrosion in the future.

How do You Replace an Anode Rod on a Water Heater?

Replacing an anode rod on a water heater is a relatively simple process. You'll need a few basic tools, and then you can replace your anode rod without any problems.

Here's a step-by-step guide for replacing the aluminum and magnesium rods in your water heater:

Step 01: Shut Off the Water Supply

Turn off the water supply to your water heater first. This can be done by turning off the valve at the bottom of your tank.

Step 02: Drain the Tank

Next, you'll need to drain the tank. You can do this by opening the valve at the bottom of your tank and letting the water drain out.

Step 03: Remove the Old Anode Rod

Once the tank is drained, you can remove the old anode rod. This can be done by unscrewing it from the tank.

Step 04: Install the New Anode Rod

Before installing the new one, make sure that you coat it with anti-corrosion plumber's grease.

Next, just carefully lower the new anode rod into the tank and screw it back in for a tight fit.

Step 05: Turn on the Water Supply

Finally, you can turn on the water supply to your tank and check for leaks. This completes your repair!

When you replace the anode rod in your water heater, it will help protect against corrosion for years to come. This simple process should only take you a few hours, and then your tank will be protected.

What's Better Aluminum, Magnesium or Zinc Anode Rod?

For harder water areas use the aluminium anode over the manganese. The aluminium anode is less expensive but tougher to install than the manganese anode, but it is not as effective at corroding.

For soft water areas use the manganese anode over the aluminium. The manganese anode is more effective at corroding but expensive and easy to install.

The zinc rod will corrode twice as fast as a magnesium rod, but is a tough installation. The zinc uses a special procedure and should only be installed by a professional.

If you are looking for the best possible protection against corrosion, a magnesium anode rod is the best option. However, it is more expensive and easy to install than an aluminum anode rod.

Tips for Maintaining Anode Rods in Water Heaters

There are a number of things you can do to ensure that your anodes stay in good shape and continue working well for as long as possible. This will help keep your water heater free from corrosion and restore its optimum performance.

Here are a few tips for maintaining hot water tank anode rods in water heaters:

- Inspect the anode rod regularly for signs of corrosion.

- Clean the tank and sediment regularly to prevent buildup that can inhibit the anode rod's performance.

- Replace the anode rod when it becomes corroded or damaged.

- Use a manganese anode rod in hard water areas and an aluminum anode rod in soft water areas.

- Keep the tank well-insulated to help prevent corrosion.

Conclusion

When it comes to choosing the best anode rod for your water heater, there are several factors to consider. Aluminium and magnesium anode rods are both effective at corroding, but they have different benefits and drawbacks.

If you have a hard water supply, you should use an aluminium anode rod. If you have a soft water supply, you should use a magnesium anode rod. We hope the information about water heater anode rod aluminum vs magnesium is clear.

Now it's time to show the world what you've just learned. Thank you for reading.

Leave a Reply